Warehouse SOP | Warehouse Standard Operating Procedures

Demands of Present-day Warehouses and Fulfilment Centres

The emergence of eCommerce-based business models has brought about dramatic changes in the strategic significance of warehouses and fulfilment centres. What it has also done is that warehouses and FCs can no longer be operated in traditional ways. These evolving demands are highlighted ahead.

Strategic Contribution and Coordination to improve warehouse efficiency

Warehouses assume strategic relevance in modern-day business models. Placed strategically, they are capable of shrinking the distance between manufacturers and customers. This means a lot when we look at it from a competition perspective as well as for achieving operational efficiency. But the operational planning must also support such strategic decisions to derive the benefits. Also, it has become nearly unfeasible to make certain business decisions without considering their ramifications on warehousing and inventory management. You can put an ad on social media saying ‘now available in stores’. But has the inventory reached the stores when you published this ad? What if there was some last-minute operational hiccup? Was your digital marketing team and supply chain team working in coordination? Did you define this coordination in the operational planning?

Securing Stock Availability

Today, the buying options are myriad for customers. If a product is not available in stores, they will get it from another store or consider buying online. If a product is not available online, they will consider getting it from a store. Stock unavailability due to mismanagement is not a qualified reason for businesses to lose customers. This is where warehouse management SOPs play a vital role. If a business is not in control of its warehouse operations, it will also lose control over its ability to maintain stock levels. The warehouse is the place where businesses can exercise rigid control over their physical and in-transit inventory via SOP for warehouse operations.Optimum Space Utilisation

Space optimization in warehouses and FCs help businesses handle more inventories per cycle. As the rentals remain more or less fixed in the short run, it only makes sense for businesses to make the most out of such fixed expenses. Service providers could also handle more business volumes without dilly-dallying on the service quality.

Integration of Technology and Process across Warehouse and Logistics

Warehousing cannot remain secluded from the need for speed and precision that has become prevalent in contemporary ways of doing business. And the answer lies in providing the same to warehousing by adopting process orientation and best-fit technological solutions. However, the presence of automated warehouse systems and processes do not assure integration between the two. This is achieved through meticulous operational planning.

Omnichannel Capabilities

As more brands and businesses are going omnichannel, warehouses cannot stay with the capabilities of the yesteryears. And empowering warehouses/FCs with omnichannel capabilities calls for major adaptations in the areas of space management, automation, manpower management, logistics, and budgeting. For example, a retail store cannot treat the store itself as a stocking place or warehouse. Among other things, it will leave a bad experience for the walk-in customers. Robust operational planning aided by automated warehouse systems is what makes the required omnichannel improvisations a reality at the ground level. If the expertise is not internally available, the option of taking external assistance from experienced warehouse automation consultants is always there. Including BPX, there are many warehouse consulting companies who could help you build these capabilities.How BPX Warehouse Consultants can help

BPX is a management consulting brand specialising in developing SOPs and process solutions. Precisely, we as warehouse management consultants help businesses with their process and operational blueprints. As a team, we have worked with 500+ clients in 25+ industries globally. Going into the future, we seek to continue our scaling efforts on the international stage. We deploy warehouse automation consultants in the design and delivery of our services. From planning to implementation, our services and solutions are worked out with due adherence to established planning and processes to achieve the degree of warehouse automation desired.

We offer this service to brands and businesses that operate their own warehouses and/or fulfilment centres. We develop robust, SOP-based processes for warehouse/ Fulfilment Centre operations encompassing inbound, outbound, and control operations. So, what we are providing here is a holistic SOP coverage for all warehouse operations. No aspect of operation shall be left out of the ambit of planning. Of course, this will involve close working with clients and clear communication of expectations and requirements. These simple warehouse SOP solutions go a long way in helping our clients elevate the operational superiority of their warehouses. If you looking forward to know about “how to run an efficient warehouse?”, then get in touch with BPX Warehouse Specialists to explore ways to improve warehouse efficiency.

Our Warehouse Solutions

- Warehouse Receiving SOPs (Inbound)

- Warehouse Picking SOPs (Outbound)

- SOPs for Warehouse Dispatch (Outbound)

- SOPs for Warehouse Operations (Control)

- Warehouse Design Consulting

Warehouse Receiving SOPs (Warehouse Inbound Process)

Maintaining robust processes for managing incoming inventory has many important business reasons:

- Warehouse storage policy

- Goods handling & storage guidelines

- Infrastructure Guidelines including warehouse racking equipments i.e. pallet racking, goods handling equipments, etc

- Facilitate outbound operations

- Quality checks for incoming inventory

- Matching inventory received with purchase details

- Accuracy of inventory data for further decision-making

- Cleanliness standards are maintained (via SOP for warehouse cleaning)

We at BPX as a warehouse automation company, develop warehouse standard operating procedures for superlative management of inbound & outbound warehouse operations. We cater to 25+ industries encompassing manufacturing, retail, distributorship, eCommerce fulfilment, and service providers.

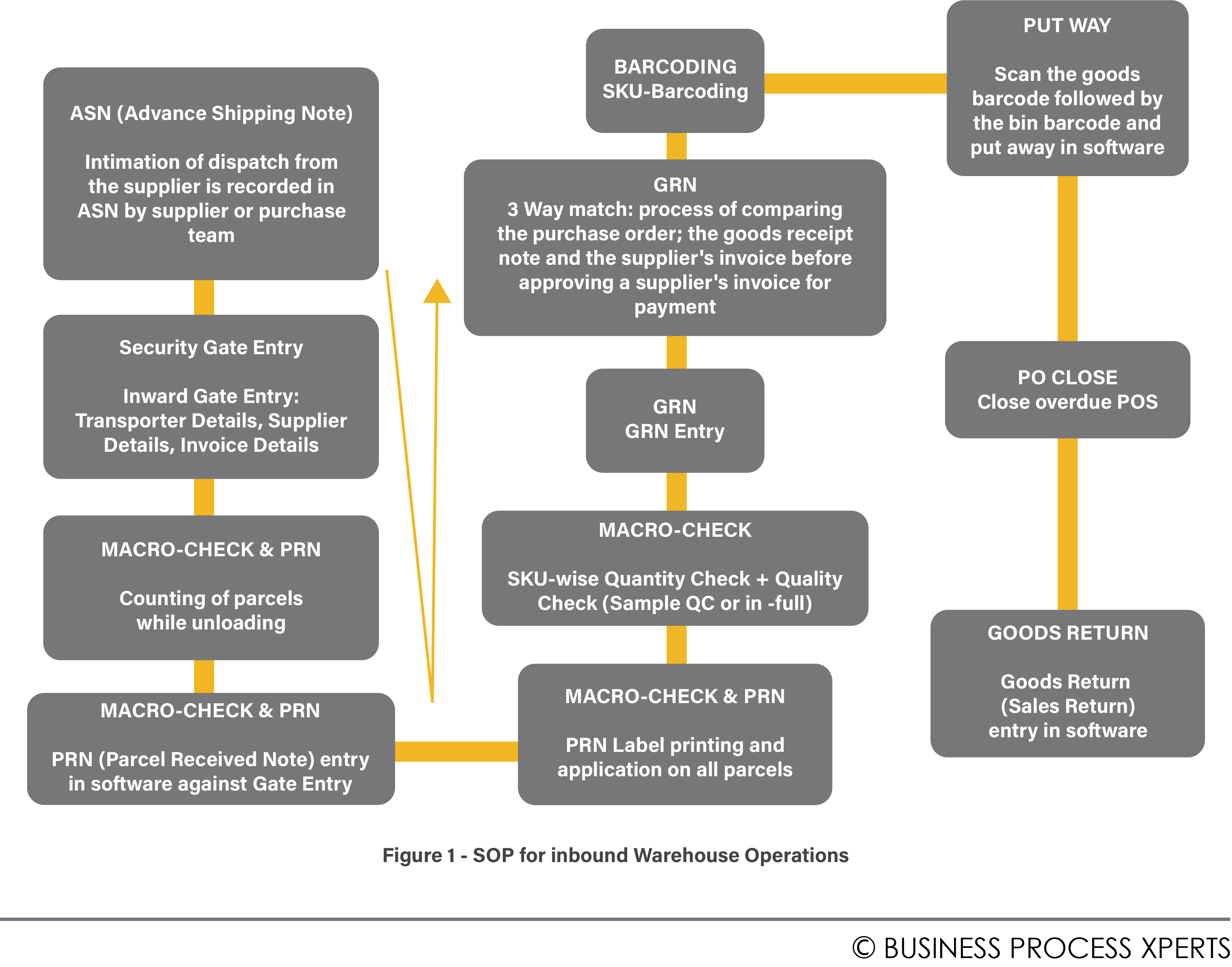

A standard SOP version for inbound warehouse operation is depicted above.

We shall customise the Warehouse SOPs (i.e. SOP for warehouse receiving) as per your unique business requirements and specifications. With a warehouse SOP list of activities, you could ensure in your business that the incoming inventories are:

- Checked for order conformity including reverse logistics

- Checked for quality

- Documented

- Properly identified and classified

- Sent to the proper shelves for storage

- Automatic storage and retrieval system

- Digitally entered into the WMS (warehouse management system)

- Compliant with outbound operational planning

- Return process is initiated on time

- WMS driven inbound process Example: SAP EWM Inbound Process

Warehouse Picking SOPs & SOPs for Warehouse Dispatch (Outbound process in warehouse)

How the outbound operations are managed in a warehouse/fulfilment centre has a bearing on other entities and business processes in the distribution network/value chain and eventually on customer/client experience. BPX helps its clients plan their outbound warehouse operations and develop the required operational planning in the form of SOPs. Given below is a standard SOP version for outbound warehouse operations.

On a reiterating note, we customise our SOP solutions (i.e. SOP for warehouse dispatch) as per clients’ unique business requirements.

Here is what we seek to help our clients achieve:

- Order processing is initiated on time

- Optimised movement for pickup

- Packing and labelling activities are matched with order details

- Coordination with logistics

- No unauthorised exit of any inventory from the warehouse/FC

- System entry/paperwork by each process owner

- Good warehousing practices

- WMS driven outbound process Example: SAP EWM Outbound Process

SOPs for Warehouse Operations (Control)

Control measures are necessary to enhance the operational efficiency of warehouses and fulfilment centres. These measures also give a window of opportunity for broader improvisations. For example, by eliminating scraps and redirecting unused assets, additional space could be generated. Our Standard Operating Procedures for Warehouse Operations stands on three pillars – Waste Control, Quality Assurance, and Continuous Improvement. What we cover under each is depicted below.

Different businesses have different approaches towards these elements. Our objective is to help clients define and map these control and improvement measures using SOPs. The concerned departments are involved in the decision-making process. The audit and action reports are meant to reach the top-level management via the organisational structure.

Warehouse Design Consulting

Any experienced warehouse design company could vouch that the warehouse layout design plays an important role in its overall functioning especially while setting up a warehouse. It affects space utilisation, movement of people and inventory, ease of accessibility, adherence to safety and security protocols, maintenance of cleanliness and hygiene, etc.

Warehouse Design and Layout planning is one of our primal proficiencies. As veterans in this field, we have witnessed the evolution of warehouse layout strategies for more than a decade.

In warehouse layout planning, our expert warehouse design consultants cover time and motion study, zone classification, mobility and accessibility, shelf management, safety and security provisions, and security aspects to eliminate pilferage. The objective is to enable our clients to enhance their business volume handling capacity and overall output with high precision and warehouse efficiency with lean space management.

Setting up a Warehouse or Improving Warehouse Efficiency

If you’re looking for setting up a warehouse or enhance efficiency of your existing warehouse operations, BPX warehouse specialists offer solutions to achieve the objective as an extended team, imparting following solutions:

- Warehouse Space Pre-Requisites / New warehouse setup checklist

- Warehouse Layout Design considering Lean Warehouse Layout

- Warehouse Management System: Vendor Search, Validation & WMS Implementation

- Warehouse Process Manuals: Digital SOPs (in form of: document, video and audio visuals in English and local language to ensure even the lowest skilled labour can grasp these SOPs). These SOPs are designed to adopt lean practices in warehouses like Kanban warehouse setup, Lean Warehouse Management ensuring the good warehousing practices are pivoted as per the requirements of the business.

- Warehouse Governance Policies: To ensure the SOPs are been adhered to, otherwise the SOPs shall just remain on paper and not being followed or adhered to

- Warehouse Automation: This includes automation with software, hardware and equipment as per the desired degree of automation i.e. semi automated, fully automated, robotic automation, basic automation, etc.

Warehouse Healthometer

Start Free Assessment

FAQs

With SOPs, you will have a planned and systematic way to execute your warehouse operations. Workflows are mapped and every task is defined to a high degree of detail. SOPs serve as an operational roadmap for employees and facilitate supervision. For more insights, we urge you to get in touch with BPX Team. Click Here.

As one of the contemporary warehouse consulting firms in the industry, we can help you modernise your warehouse as follows:

- First, we can help you define the operational planning of your warehouse operations.

- Second, we can help you find the right WMS system i.e. Warehouse Management System for your warehouse operations management (Example: SAP WM/ SAP Warehouse Management, Odoo Inventory, Epicor WMS, Oracle WMS, Zoho Inventory and/or any other WMS system which can be best-fit for the business)

- Third, our warehouse experts shall define digital SOPs in english and local spoken language to ensure even the lower skilled manpower is able to understand and perform as per the SOPs

- Fourth, Implementation support wherein we do not just consult but also help you to implement and monitor.

Our warehouse setup consultant can help you set up your Warehouse in the following ways:

- Defining Warehouse Setup Plan/ Critical Pathway

- Warehouse Layout Planning

- Warehouse Operations SOPs

- Finding the right WMS solution (warehouse management system)

- Process-IT integration

Get in touch with BPX Warehouse Specialists to explore how BPX can help you set up your warehouse.

ERP covers all the aspects of business i.e. accounts, inventory, procurement, etc. Wherein WMS is the backbone of warehouse management. Most ERPs have the WMS as a module and sometimes an external WMS is integrated with the ERP. In both cases, ERP and WMS integration is key for automation because the trigger point starts from ERP i.e. Procurement Process wherein PO is generated, followed by Goods inbound and outbound process in WMS, followed by accounting and taxation effect based upon inbound and outbound of goods. Thus, beginning happens with procurement and ends with the accounting module within the ERP wherein WMS is the mediating module between the two and without having these modules within ERP, warehouse automation cannot be achieved.

Warehouse good practices involves understanding best-practices i.e. lean warehouse management, kanban warehouse management and industry standard practices, but at the same time pivot it to existing needs of the business considering the resources available, team size, industry and scale of business. Thus, blindly adopting best practices can be a disaster. Thus, BPX warehouse specialists shall develop a custom warehouse plan to manage each and every process within the warehouse and help achieve business objectives and within the desired budgets.

SOPs designed by BPX experts shall help to define the following parameters for each activity within the warehouse:

- Process Name

- Process Owners

- List of activities performed within each process

- Activity owner mapped to each step and identifying multiple people involved within the process

- Software being used at each step along with the software work-flow defined with screenshots

- Reports to be generated with their templates

- Identifying Gaps in the As-Is process

- Defining the To-Be process

BPX Warehouse Specialists shall help you to create SOPs for warehouse and also ensure these SOPs are being implemented.

Warehouse Management System (also called as: WMS) helps to capture all the following transactions:

- Inbound and outbound transactions of the warehouse

- Bin Management (i.e. Put Away, Picklist) for optimum space management

- FIFO Management

- Manage multiple warehouses/ stockpoints

- Manage storage and tracking of multiple SKUs at multiple locations within the warehouse

- Stock Level updates at real-time

- Track Inventory Levels and Pilferages with Inventory Counts Module

- Team performance tracking working at warehouse

WMS can be an independent software integrated with the ERP or a module within an ERP.

WMS is the backbone of warehouse management.

To help identify or implement WMS, get in touch with BPX Warehouse Specialists. Click Here.

There are numerous WMS softwares available, to name a few global WMS softwares are: SAP WM, Oracle WMS, Infor WMS, Odoo Inventory, Zoho Inventory, Manhattan WMS, Microsoft Dynamics 365 Supply Chain Management, etc

Thus, choosing the best-fit for your business becomes chaotic from the long list available. Few prerequisites to look into before choosing best WMS, are as follows:

- Business existing scale and volumes v/s expected in the next 03-05 years

- Budgets and ROI Analysis to implement new WMS

- Skilled manpower available v/s required to implement the WMS

- Warehouse Layout and flow of goods, as it shall impact the processes defined within the WMS

- As-Is Warehouse Process

The above parameters shall act like an input data to BPX Warehouse Consultants, who shall then study and curate the requirements of the WMS. Based on the requirement list, BPX team shall evaluate the WMS vendors and help to implement it.

WMS implementation duration differs between 01 to 04 months, depending upon following parameters:

- Product classification and product master readiness

- Total bin locations allocated

- Total team members to be trained who shall be working on WMS

- Total Warehouse locations and size of each warehouse

- Complexity of warehouse operations i.e. Inbound, Outbound, Kitting, Parent-child SKUs, etc

BPX team defines the roadmap for the complete implementation plan and esure the timelines are abided by with a strong team of warehouse consultants and project managers.

Key 06 major objectives of warehouse design and layout are as follows:

- Lean layout planning to ensure maximum space utilisation without wastage

- Warehouse process mapping aligned with flow of goods

- Reduce goods handling touchpoints and reduce goods handling damages

- Reduce wastage of labour with time & motion analysis

- Technology enabled across warehouse layout i.e. Bin locations, Robotic Automation, Security Surveillance Hardware devices

- Space allocation as per required zones and mapping of furniture, fixtures and equipments

05 Key elements for warehouse automation are as follows:

- Automation with Software/ WMS

- Automation with Robotic devices for goods handling and packaging

- Automation with Hardware devices for security surveillance

- Automation in MIS for early warning signals

- Automation in Inventory count and tracking

Automation is a broad term, thus it’s important to decide the degree of automation required i.e. semi-automated, fully-automated, hybrid, low automated warehouse.

Automation requires resource planning in terms of human capital and monetary investment into software/ hardwares for automation along with initial setup one-time investments and costs. The first step towards automation is defining As-Is process for all processes to be automated, analyse the gaps which automation can help resolve and the To-Be process post automation and its efficiency that can be achieved.

Thus, ROI-Analysis and Gap-Analysis are the key activities to assess the feasibility of automation required.

BPX Warehouse Specialists help clients to automate their warehouse along with ROI-Analysis.